BHS series Double Suction Split Casing pumps

Remarks:

We have been OEM for many brands from Europe and our pumps has been used by famous brands from Middle east to apply for UL/FM Certificate.

We can make pumps with the bearing housing as your own design.

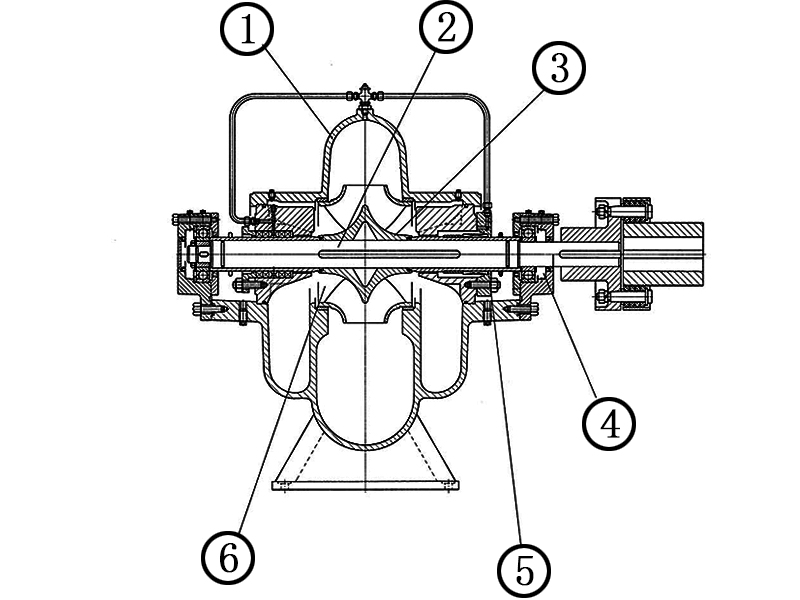

Constructure

1、Innovative casing:

—In-Iine design

—short distance between bearings and corre spondingly short shaft

—leak-tight due to compact joint flange with long, prestressed bolts

—counter-rotation possible with similar parts

—double volute version for appropiate total heads

—easy mounting - self-aligning upper casing

2、Service-friendly shaft:

—completely sealed and dry for zero corrosion

—short and rigid with negligible vibrations

—replaceable shaft protecting sleeves

—no threads exposed to pumped medium long oper ating life and no corrosion

—adjustment- free assembly

—quick and easy assembly /dimantling of the rotor components due to elastically prestressed mountings

3、High-performance impeller:

—minimal axial thrust due to double-entry impeller

—optional impeller wear rings

—new vane passage with excellent hydraulic characteristics

6、Excellent efficiencies, Outstanding NPsH:

—computer -optimized double entry impellers

—smooth surfaces inside the casing and on the Impeller

—smooth, quiet running also guaranteed by a large Impeller eve area

—no drop in efficiency due to cost effective re placeable casing wear rings and impeller wear rings

—smooth. low loss running due to a swirl-free inlet

5、Application -orientated seals:

—asbestos-free, potable water quality soft-packed stuffing boxes

—optional: mechanical seals

4、Long-life bearings

—covered, sealed for life grease lubricated antifriction bearings for a long service life

—open gland, i. e. enough space for service activities

—optional: oil lubrication with constant level oiler

| 1 | pump casting | 8 | seal housing | 15 | circlip |

| 2 | impeller | 9 | packing gland | 16 | bearing block |

| 3 | pump cover | 10 | block water ring | 17 | bearing sleeve |

| 4 | flushing water piping | 11 | bearing cover | 18 | shaft sleeve |

| 5 | sealring | 12 | bearing housing | 19 | stuffing seals or mechanical |

| 6 | vent plug | 13 | shaft | 20 | bearing sleeve |

| 7 | O-ring | 14 | radial seal ring | 21 | nut |

| 1 | pump casting | 8 | vent plug | 15 | bearing block ring | 22 | residur bearing |

| 2 | pump cover | 9 | seal housing | 16 | circlit | 23 | O-ring |

| 3 | sleeve | 10 | flushing water piping | 17 | radial seal ring | 24 | residur bearing cover |

| 4 | shaft | 11 | packing gland | 18 | bearing | 25 | base |

| 5 | impeller | 12 | bearing cover | 19 | motor stool | ||

| 6 | sealring | 13 | bearing body | 20 | stuffing seals or mechanical | ||

| 7 | shaft sleeve | 14 | bearing block | 21 | second sleeve | ||

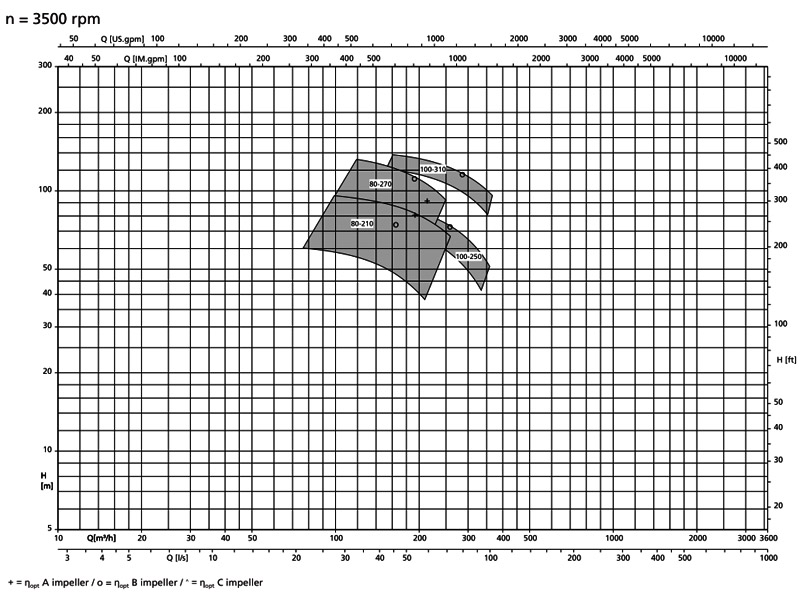

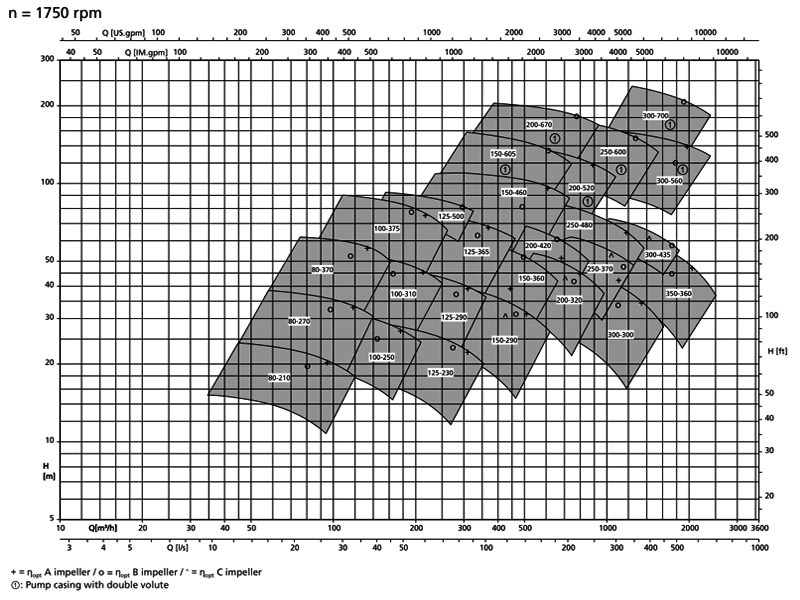

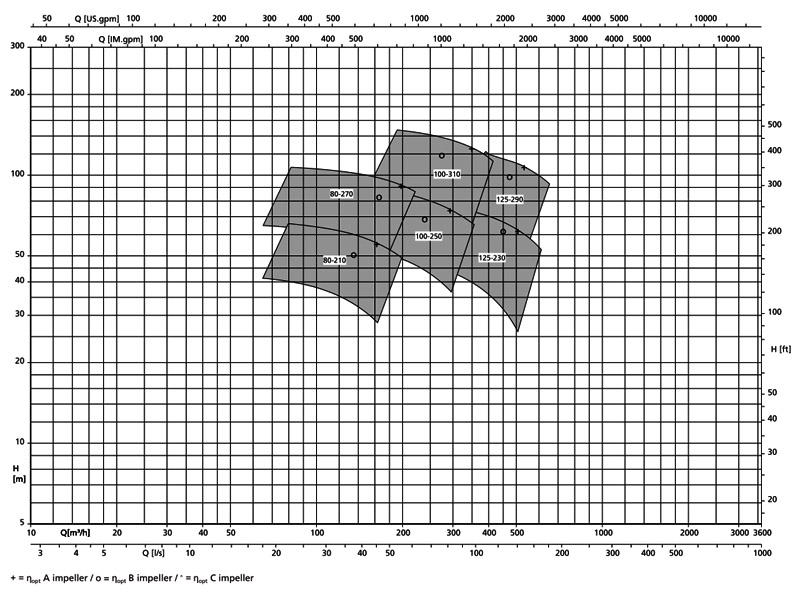

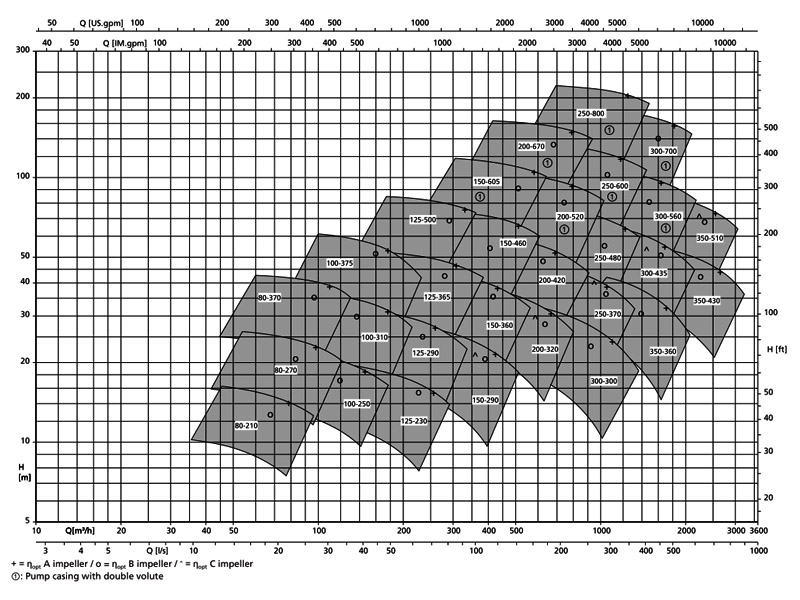

Performance Curve

Selection charts

Omega / Omega V; n = 2900 rpm

Omega / Omega V; n = 1450 rpm

Omega / Omega V; n = 3500 rpm

Omega / Omega V; n = 1750 rpm