Factory For China Vertical Wet Pit Sump Pump with Vertical Motor (VTP)

Being supported by an innovative and experienced IT team, we could present technical support on pre-sales & after-sales service for Factory For China Vertical Wet Pit Sump Pump with Vertical Motor (VTP), We sincerely welcome all guests to set up business relationships with us on the basis of mutual benefits. Please contact us now. You will get our professional reply within 8 hours.

Being supported by an innovative and experienced IT team, we could present technical support on pre-sales & after-sales service for China Wet Pit Pump, Pump, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you.

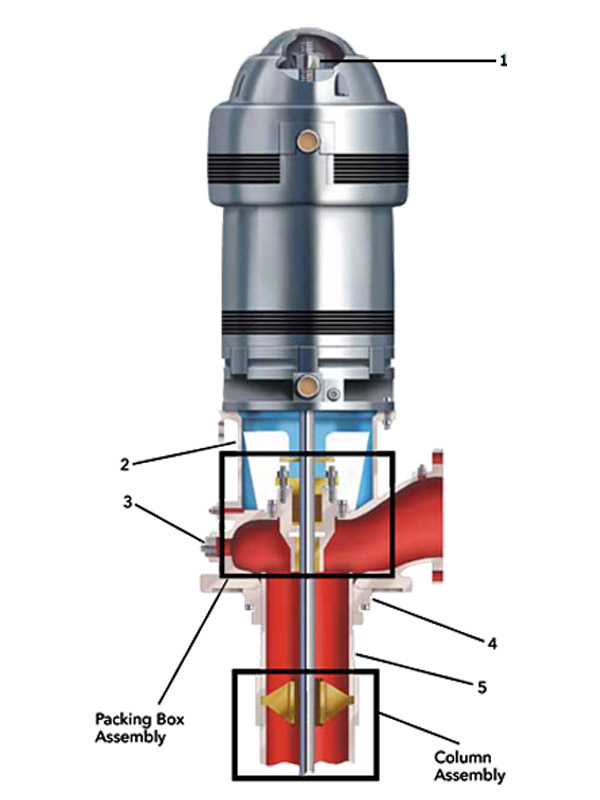

Constructure

Water Lubrication

1 Adjusting Nut

Permits exact impeller adjustment for

maximum performance.

2 Discharge Head

Heavy-duty head provides maximum

accessibility to service packing box

assembly. Two piece head shaft is standard.

3 Prelube Connection

4 Column Adapter

Accepts threaded or flanged column.

5 Adjusting Nipple

Threads directly into column adapter.

Headshaft stickup set exactly by threading

head on column as required.

6 Discharge Bowl Bearing

Bronze.

7 Discharge Bowl

Close grained cast iron.

8 Pump Shaft

Oversized high strength polished stainless

steel.

9 Intermediate Bowls

Close grained cast iron. Waterways glass

lined for maximum efficiency.

10 Impellers

Silicon bronze, designed for maximum

efficiency. Precision balanced for smooth

operation.

11 Intermediate Bowl Bearings

Bronze or rubber for long pump life under

any well conditions.

12 Lock Collets

Steel construction secures impeller to

pump shaft.

13 Sand Collar

Accurately located at suction bowl bearing

to eliminate possible sand buildup.

14 Suction Bowl Bearing

Bronze. Grease packed for long trouble-

free life.

15 Tail Pipe or Strainer — Optional

Optional tail pipe cut to desired length for

best suction conditions. Strainer provides

protection from large solids

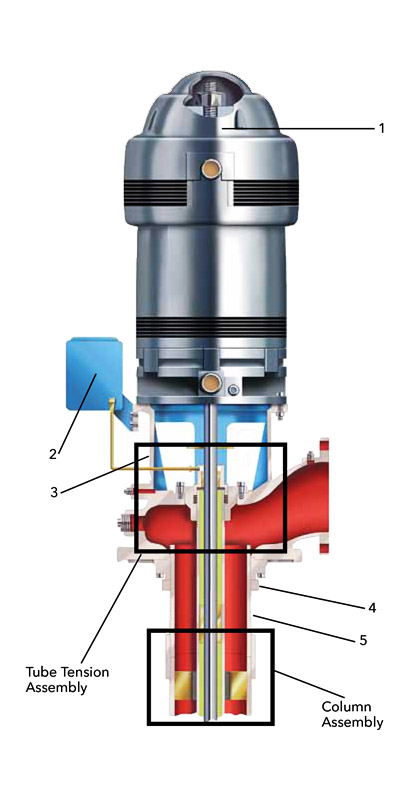

Oil Lubrication

1 Adjusting Nut

Permits exact impeller adjustment for maximum performance.

2 Large Capacity Manual or Solenoid Oiler

Assures constant oil supply.

3 Discharge Head

Heavy-duty head provides maximum accessibility to service tube tension assembly. Two piece headshaft is standard.

4 Lock Ring

Positively locks adjusting nipple to discharge head.

5 Adjusting Nipple

Threads directly into column adapter.Headshaft stickup set exactly by threading head on column as required.

6 Tube Adapter Bushing

Bronze.

7 Double Bowl Seal — Optional

Provides positive sealing of developed head.

8 Pump Shaft

Oversized high strength polished stainless steel.

9 Discharge Bowl

Close grained cast iron. Relief ports insure positive bearing lubrication.

10 Discharge Bowl Bearing

Bronze. Close tolerance fit for minimum leakage.

11 Impellers

Silicon bronze. Designed for maximum efficiency.Precision balanced for smooth operation.

12 Intermediate Bowls

Close grained cast iron. Waterways glass lined for maximum efficiency.

13 Intermediate Bowl Bearings

Bronze or rubber for long pump life under any well conditions.

14 Lock Collets

Steel construction secures impeller to pump shaft.

15 Sand Collar

Accurately located at suction bowl bearing to eliminate possible sand buildup.

16 Suction Bowl Bearing

Bronze. Grease packed for long trouble-free life.

17 Tail Pipe or Strainer — Optional

Tail pipe cut to desired length for best suction conditions. Strainer provides protection from large solids.

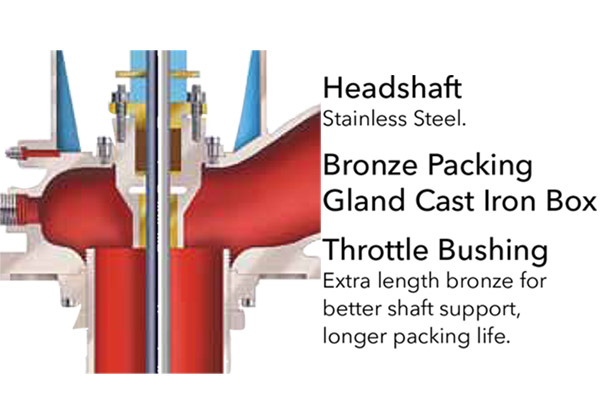

Headshaft

Steel.

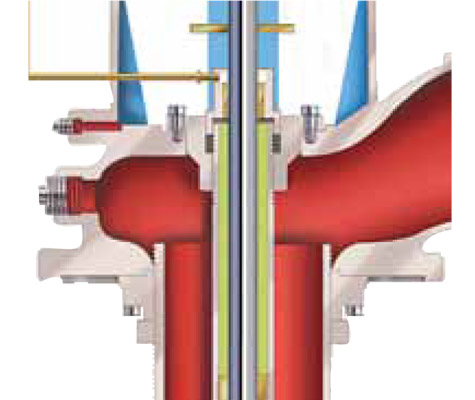

Tube Tension Nut

Heavy-duty cast iron.

Tension Nut Bushing

Bronze construction. Spiral groove insures

positive lubrication to lineshaft bearings.

Heavy-Duty Tension Plate

For positive alignment of lineshaft bearings