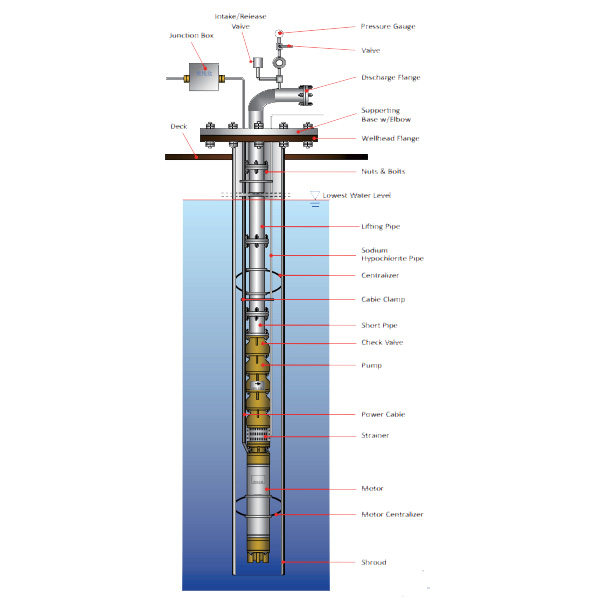

ESP series Eletric Submersible pumps

Anti-corrosive Motor

(1)Stainless Steel Head and Base

(2)Stainless Steel Housing

(3)Rotor-retaining Bearing

(4)HSN or AFLAS O-rings

(5)Monel K-500 Bolts

High-temperature Motor

(1)For 180℃ -230℃ (356F -446F) Downhole Temperature

(2)Upgraded Materials to Achieve High-temperature Rating,Premiumlnsulation and Excellent Conductivity

(3)All-steel Stator

(4)AFLAS or FFKM O-rin

Permanent Magnet Motor(PMM)E3

(1)Standard vSD-Lower Cost and higher reliability.Power Factor >0.92

(2)Efficiency >0.92

(3)Optional Anti-corrosion productStandard bolt

(4)Compatible with all existed ESP gauge.

Asynchronous Motor

Power Capacity Range

| Casing Dia. in(mm |

Applicable Downhole Temp. |

Series | Single Tandem Power HP |

Max. Shaft Power HP |

||

| C | 50HZ | 60HZ | 50HZ | 60HZ | ||

| 4-1/2(114.3) | 150 | 375 | 50 | 60 | 150 | 180 |

| 5-1/2(139.7) | 150 | 107D | 100 | 120 | 200 | 240 |

| 5-1/2(139.7) | 150 | 456 | 100 | 120 | 330 | 400 |

| 456D | 180 | 216 | 417 | 500 | ||

| 7(177.8) | 150 | 540 | 167 | 200 | 500 | 600 |

| 540D | 250 | 300 | 600 | 720 | ||

| 9-5/8(244.5) | 150 | 562 | 340 | 408 | 500 | 600 |

| 562D | 380 | 456 | 760 | 912 | ||

| 9-5/8(244.6) | 120 | 738 | 593 | 714 | 1190 | 1428 |

| Permanent Magnet Motor | |||

| Series | Power Range HP |

Power Range kW |

Current Range A |

| 450 | 48~432 | 36~322 | 28~73 |

| 562 | 100~1000 | 75~746 | 41~139 |

Remark:

(1)4 poles construction

(2)Max. 400F(204℃) winding Temperature

(3)Standard: #45CS head, base and housing

(4)Anti-corrosion: SS head and base, 9Cr1Mo housing

PROTECTOR

Parameters Range

| Optimum Well Diameter in (mm |

Series | Max. Optimum Well Temperature |

Max. Transmitted Power [HP] |

Max. Thrust Capacity [Lbs |

|||

| F | C | 60HZ | 50HZ | 60HZ | 50HZ | ||

| 4-1/2 [114.3] |

338/375 | 300 | 150 | 240 | 200 | 2500 | 3000 |

| 5-1/2 [139.7] |

387/456 | 300 | 150 | 240 | 200 | 8600 | 10320 |

| 5-1/2 [139.7] |

400/456 | 300 | 150 | 240 | 200 | 8600 | 10320 |

| 7 [177.8] |

513/540 | 300 | 150 | 600 | 500 | 12000 | 14400 |

| 7 [177.8] |

538/540 | 300 | 150 | 600 | 500 | 12000 | 14400 |

| 9-5/8 [244.5] |

675/738 | 300 | 150 | 962 | 802 | 20000 | 24000 |

We also provide the following products:

(1)387/107 Series Protector

(2)387/456, 513/540 Series Protector for Vertical Water Injection Pump

(3)All Series of Anti-corrosive Protector with Monel K-500 Coating

(4)All Series of Abrasive-resistant Protector

(5)All Series of Protector for High-temperature Motor

SEPARATOR AND INTAKE

Series and Specification

| Series | OD in[mm] | Min. Casing OD Din[mm] | Shaft Diameter in[mm] |

| 338 | 3.38 [85.9] | 5.5 [139.7] | 11/16 [17.424] |

| 387 | 3.87 [98.3] | 5.5 [139.7] | 7/8 [22.225] |

| 400 | 4.00 [101.6] | 5.5 [139.7] | 7/8 [22.225] |

| 513 | 5.13 [130.3] | 6.625 [168.3] | 1.187 [30.15] |

| 675 | 6.75 [172] | 8.625 [219] | 1.187 [30.15] |

PUMP

Rate Range

| Series | OD in[mm] |

Min. Casing OD in[mm] |

Min. Rate 60HZ[BPD] |

Max. Rate 60HZ[BPD] |

Min. Rate 50HZ[M3/D] |

Max. Rate 50HZ[M3/D] |

| 338 | 3.38 [85.9] |

4.5 [114.3] |

250 | 2500 | 30 | 300 |

| 387 | 3.87 [98.3] |

5.5 [139.7] |

150 | 6800 | 20 | 900 |

| 400 | 4.00 [101.6] |

5.5 [139.7] |

150 | 6800 | 20 | 900 |

| 540 | 5.13 [130.3] |

6.625 [168.3] |

1100 | 14000 | 150 | 1800 |

| 538 | 5.38 [136.6] |

7 [177.8] |

1100 | 15000 | 150 | 2000 |

| 562 | 5.62 [142.7] |

7 [177.8] |

7500 | 31700 | 930 | 4200 |

| 675 | 6.75 [172] |

8.625 [219] |

7000 | 33000 | 900 | 4300 |

| 862 | 8.62 [218.9] |

10.75 [273] |

11500 | 30000 | 1520 | 3975 |

Remark: We also provide the following products:

(1)Vertical Water Injection Pump for all series

(2)Anti-corrosive pump for all series

Gas Handler Specification

| Series | Rate Range 50HZ m3 |

Type | Stage | Housing | Shaft Dia |

| 387/400 | <150 | VDS150 | 46 | #60 | 0.875 |

| >300 | VDS300 | 35 | #60 | 0.875 | |

| 540 | <400 | VDS400 | 21 | #40 | 1.187 |

| 400~600 | VDS600 | 14 | #40 | 1.187 | |

| >800 | VDS800 | 14 | #40 | 1.187 |

BEKENFLO Medium Voltage VSD

BEKENFLO Medium Voltage VSD is a frequency converting equipment specially designed for ESP applications. Highly intellectualized with three-level topology structure and neutral point potential automatic clamping function, it has passed the type tests by CCDT and FUJIAN TEST INSTITUTE FOR GENERATION & DISTRIBUTION & ELECTRIC CONTROL EQUIPMENT.

● The three-level topology structure makes the maximum turn-off voltage of every IGBT device

to 1/2 of the DC link voltage.

● The three-level topology structure decreases dv/dt of the inverter’s output voltage.

● Neutral point potential automatic clamping

● Low switching loss

● Compact in structure, highly reliable

Specification

● Capacity: 45kVA-540kVA

● Voltage Rating: 0.6kV-2.6kV

● Output Frequency: 0-150Hz

Main Features

● Protection against overvoltage, undervoltage,

overcurrent, default phase and short circuit

● LED display for output current, voltage, frequency

● Keyboard input of system parameters

● Operate at variable frequency or mains frequency

● Manual/Auto startup at variable frequency

● Adjustable startup time and startup frequency

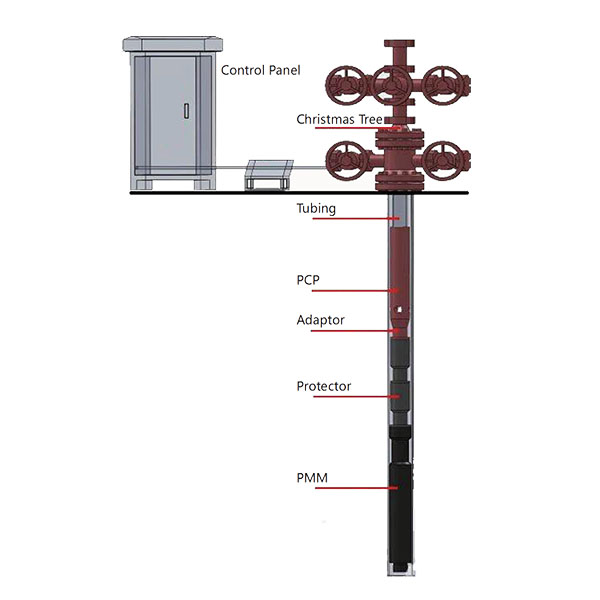

ESPCP (Electrical Submersible Progressing Cavity Pump) System

ESPCP is the recently developed oill lifting equipment featuring the advantages of ESP and PCP. They eliminate the rod wearing

and offer a more efficient and cost saving solution in terms of operation and maintenance.

ESPCPs are suitable for a wide range of well conditions including viscous, gassy and abrasive applications.

ESPCP is the submersible motor driven progressing cavity pumping system. Integrating designing and functional advantages, they save the energy by 30%~60% when compared with rod pumps. Since it provides deeper pump setting depth than that of rod

pumps, they also can be used in the various applications, including heavy oil wells, sand producing wells, gas wells, deviated wells and horizontal wells.

ESPCPs are widely used for coalbed methane dewatering. They can handle abrasives, such as coal fines, while maintaining production efficiency with low pump intake pressure.

● Rapid Response

● Custom Design

● Safe and Reliable

● 3-Key Alignment: Easy alignment and adjustment

● Easy installation without excessive cable torquing

| Max Amperage | 140 A,154 A or 205 A |

| Max Voltage | 5000V |

| Max Pressure | 5000 PSI STD |

| Max Temperature | 325℉ |