BPK series End Suction Centrifugal Pumps

Application Std:Design Std ISO 2858, Flange std can be BS,DIN,ISO,etc

Remarks: We have been OEM for many brands from Europe and USA

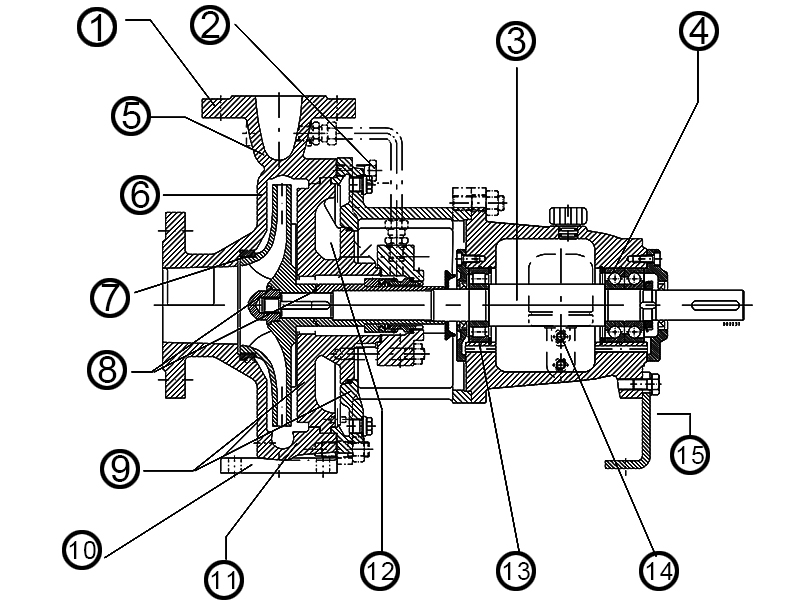

Constructure

Benefits at a Glance

1、Easy to replace

due to standardized pump and flange design

2、Easy to dismantle

due to forcing screws

3、Durable

Dimensioned to ensure a bearing life of more than 25,000 operating hours and a shaft deflection of less than 0.05 mm

5、Reliable

due to well-proven hydraulic system

6、Safety

ensured by strength analysis and quality casting with corrosion allowance

7、Low operating costs

due to replaceable casing wear rings and impeller wear rings

8、Cost-effective main-tenance

due to dry shaft (no special materials required) and shaft protecting sleeve

9、Small spare partsstock

due to modular design system

4、Reliable

due to sturdy bearings and oil lubrication

15、Sturdy

Support foot minimizes shaft displacement in the coupling area

10、Easy to dismantle

due to back pull-out design: the casing may remain in the pipeline when the pump is dismantled

11、Long service life

of bearings and mechanical seals due to low radial forces

12、Versatile

due to wide range of materials and many design variants, e.g. cooling or heating

13、Maintenance-friendly

Radial bearing ensures easy assembly and permits thermal expansion of the shaft

14、Easy to service

due to constant-level oiler: constant lubrication, easy to check

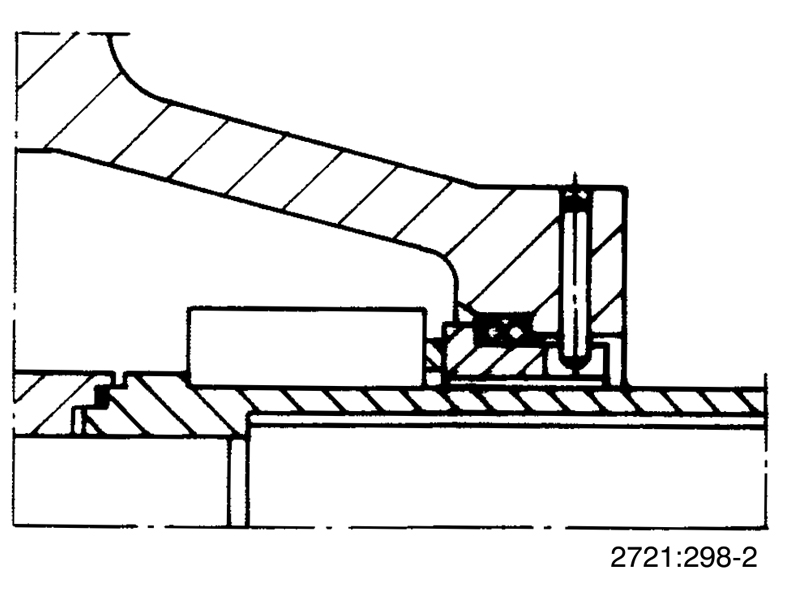

Design variant

Casing cover with conical seal chamber

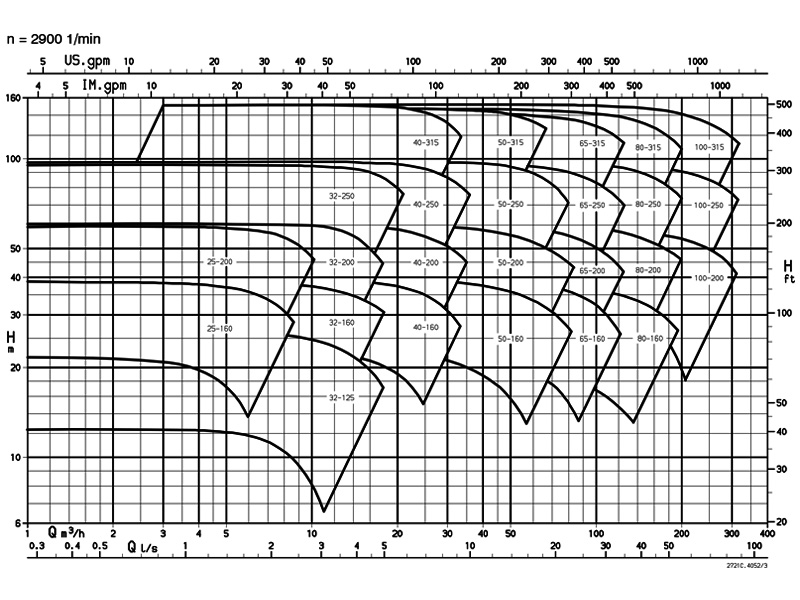

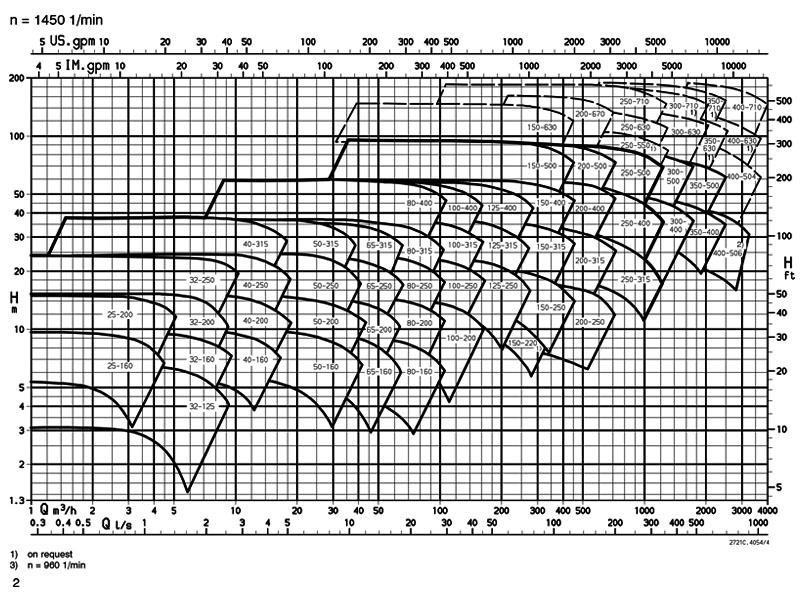

Performance Curve